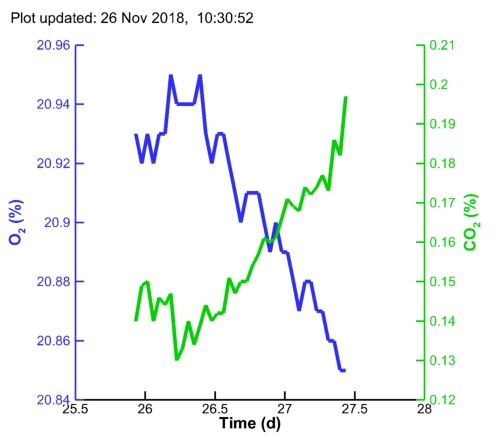

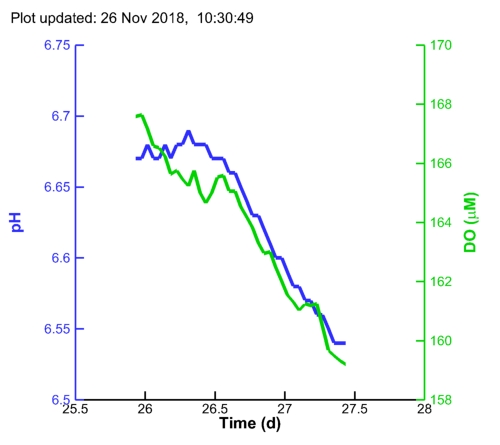

| MC1 pH: |

Trace_2018-10-30_19h52_pH_243632-2353-1178.txt,

Trace_2018-11-12_12h53_pH_243632-2353-1178.txt

|

| MC1 DO: |

Trace_2018-10-30_19h52_DO_242453-02-210052.txt,

Trace_2018-11-12_12h53_DO_242453-02-210052.txt

|

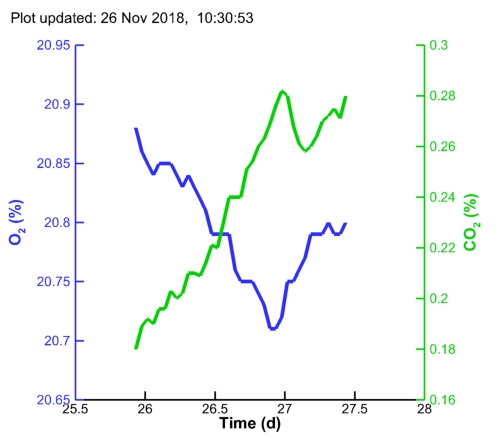

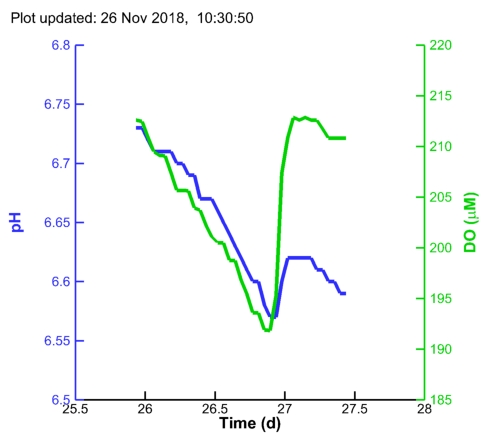

| MC2 pH: |

Trace_2018-10-30_19h53_pH_243632-2353-1176.txt,

Trace_2018-11-12_12h53_pH_243632-2353-1176.txt

|

| MC2 DO: |

Trace_2018-10-30_19h53_DO_242453-02-210053.txt,

Trace_2018-11-12_12h54_DO_242453-02-210053.txt

|